In the global quest for fresh water, seawater desalination stands as a beacon of hope. Every day, over 16,000 desalination plants worldwide produce nearly 100 billion liters of fresh water, quenching the thirst of cities and industries. But behind this modern miracle lurks an ancient, relentless adversary: corrosion.

Saltwater is one of the most corrosive natural substances on Earth. For the engineers and operators of these critical facilities, the battle against rust, degradation, and system failure is constant. It’s an unseen enemy that eats away at metal pipes, compromises sensitive membranes, and drives up operational costs, threatening the very viability of the process.

Traditional materials like stainless steel and even specialized alloys eventually succumb to the combined assault of high-pressure brine, chemical treatments, and microbial activity. But what if there was a material that was virtually immune to this attack? A material that could form an impenetrable shield, ensuring decades of reliable service in the harshest marine environments?

This is the story of Expanded Polytetrafluoroethylene (ePTFE) and how it’s revolutionizing the durability and efficiency of seawater desalination plants. At SUKO, we have first-hand experience witnessing this transformation, engineering solutions that tackle the core challenges of the industry.

The Billion-Dollar Problem: Why Corrosion is More Than Just Rust

To truly appreciate the solution, we must first understand the scale of the problem. Corrosion isn’t just a cosmetic issue; it’s a fundamental threat to operational integrity. According to a landmark study by AMPP (formerly NACE International), the global cost of corrosion is estimated at a staggering $2.5 trillion annually, representing over 3% of the global GDP.

In a seawater desalination plant, these costs manifest in several ways:

- Equipment Failure: A corroded pipe or fitting can lead to catastrophic leaks, forcing costly and unplanned shutdowns.

- Reduced Efficiency: Corrosion byproducts can flake off and foul sensitive components like reverse osmosis membranes, reducing water output and increasing energy consumption.

- Contamination: Leaks can introduce contaminants into the purified water stream, posing a public health risk.

- Constant Maintenance: A significant portion of a plant’s maintenance budget is dedicated to inspecting, repairing, and replacing corroded parts.

The primary culprits are chloride ions, which are abundant in seawater. They aggressively attack the passive protective layers of most metals, including many grades of stainless steel, leading to pitting and crevice corrosion. Add chlorine—a powerful oxidizing agent used for disinfection—to the mix, and you have a perfect storm for material degradation.

The Limits of Traditional Materials: A Losing Battle

For years, engineers have relied on a handful of materials to build desalination systems, each with its own set of compromises.

| Material | Seawater Corrosion Resistance | Chlorine Resistance | Biofouling Resistance | Key Drawback |

|---|---|---|---|---|

| 316L Stainless Steel | Good | Moderate | Poor | Susceptible to pitting & crevice corrosion from chlorides over time. |

| Duplex Stainless Steel | Very Good | Good | Poor | High initial cost; can still corrode under specific conditions. |

| Titanium | Excellent | Excellent | Poor | Extremely high cost, making it prohibitive for widespread use. |

| PVC/CPVC | Excellent | Good | Moderate | Limited pressure and temperature ratings; can become brittle. |

| FRP (Fiberglass) | Good | Moderate | Poor | Prone to delamination and chemical attack from long-term exposure. |

While some of these materials offer good performance in certain areas, none provide a complete, cost-effective solution against the trifecta of challenges: salt, chlorine, and biological growth. This is where the unique molecular structure of ePTFE changes the game.

Enter the Champion: What is ePTFE and Why is it Different?

You’ve likely heard of PTFE, most famously known by the brand name Teflon™. It’s renowned for its non-stick properties and chemical inertness. Expanded PTFE (ePTFE) takes these properties to an entirely new level.

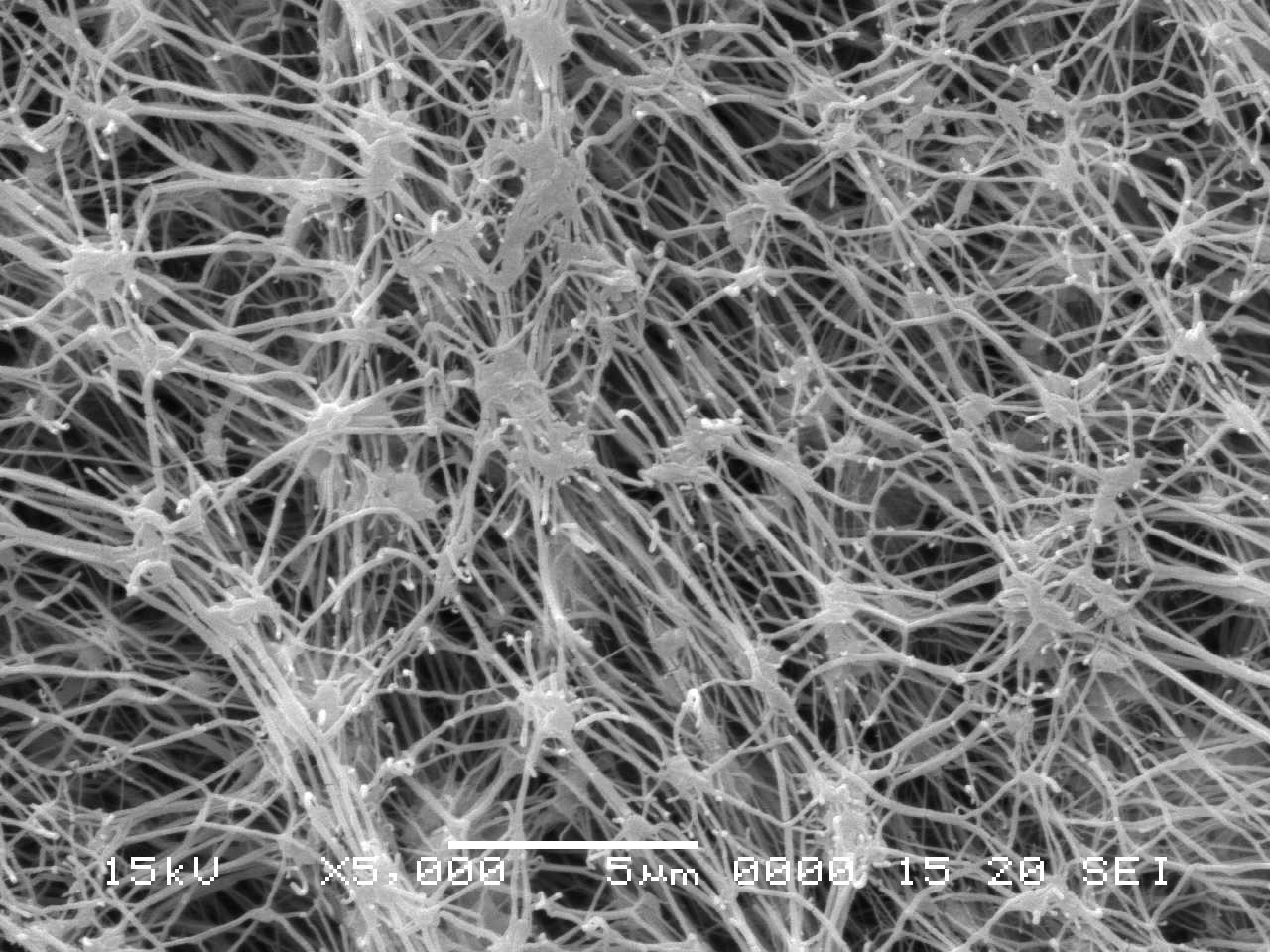

ePTFE is created by rapidly stretching PTFE under specific conditions. This process transforms the solid material into a microporous structure of incredible strength, composed of solid nodes interconnected by a web of tiny fibers.

This unique structure gives it a combination of properties that make it ideal for extreme environments:

- Chemical Invincibility: Like its predecessor, ePTFE is chemically inert to nearly all industrial chemicals, including concentrated acids, alkalis, and solvents. Seawater and brine simply have no chemical pathway to attack it.

- Hydrophobic Nature: The material is intensely water-repellent. Water beads up and rolls off its surface, preventing it from soaking in or clinging to the tube walls.

- Temperature Resilience: It can handle a vast range of temperatures, from cryogenic lows to highs of over 260°C (500°F), without losing its integrity.

- Durability and Flexibility: Despite its porous appearance, it is remarkably strong and flexible, able to withstand high pressures and mechanical stress.

This unique combination of features directly addresses the core failures of traditional materials in desalination.

Unbeatable ePTFE Seawater Corrosion Resistance

The fundamental advantage of ePTFE is its near-total immunity to saltwater. The carbon-fluorine bond, one of the strongest in organic chemistry, forms a molecular fortress that chloride ions cannot breach.

- No Pitting or Crevice Corrosion: Unlike metals, ePTFE has no free electrons to give up in an electrochemical reaction. Corrosion simply cannot start.

- Brine Handling: It is completely unaffected by the highly concentrated brine reject from reverse osmosis systems, a stream that is often even more corrosive than the initial seawater intake.

- Longevity: An ePTFE tube or liner can last for decades in a marine environment with virtually no degradation, drastically reducing the total cost of ownership.

This is why marine grade ePTFE tubing is not just a component; it’s a long-term investment in reliability.

The Chlorine Shield: The Power of Chlorine Resistant PTFE

Chlorine is essential for preventing biological growth in intake pipes and pre-treatment systems. However, it is a powerful oxidizer that degrades many plastics and accelerates the corrosion of metals.

Standard PTFE is already highly resistant to chlorine, but the enhanced structure of ePTFE provides an even more robust barrier. It doesn’t swell, weaken, or become brittle when exposed to chlorinated seawater, even over long periods. This ensures that critical reverse osmosis system components, such as the tubing leading to and from membrane housings, maintain their structural integrity and don’t leach harmful chemicals into the system.

A plant in the Arabian Gulf, which operates in some of the world’s most saline and biologically active waters, faced recurring failures in the chemical dosing lines of its pre-treatment system. After switching to SUKO’s Corrosion-Proof Expanded PTFE Tube, they eliminated unscheduled maintenance for these components and saw a measurable improvement in system uptime.

The Non-Stick Solution: Biofouling Prevention ePTFE

Biofouling—the accumulation of microorganisms, algae, and marine life on wet surfaces—is a massive operational headache. It clogs pipes, reduces flow rates, and can damage sensitive equipment.

The extremely low surface energy of ePTFE makes it incredibly difficult for organisms to attach and colonize. Its hydrophobic and non-stick nature creates a surface that is essentially self-cleaning.

- Reduced Cleaning Cycles: Systems using ePTFE tubing require far less frequent cleaning (pigging) and chemical flushing.

- Lower Chemical Use: By naturally resisting biofilm formation, plants can reduce their reliance on biocides and other harsh chemicals, lowering both cost and environmental impact.

- Sustained Performance: By preventing the buildup that restricts flow, ePTFE helps maintain the plant’s designed efficiency, saving energy on pumping.

This makes it an ideal material for seawater intake pipelines, ship ballast water systems, and any application where biological growth is a concern.

SUKO: Engineering ePTFE for Peak Desalination Performance

Understanding the science of ePTFE is one thing; engineering it into a reliable industrial product is another. At SUKO, we specialize in harnessing the power of this remarkable material to solve real-world industrial challenges.

Our Corrosion-Proof Expanded PTFE Tube for Seawater Desalination Plants is not an off-the-shelf product. It is a purpose-built solution designed with the specific demands of the marine industry in mind.

We have engineered our marine grade ePTFE tubing to excel in the most critical applications within a desalination facility:

- Desalination Membrane Housings: Providing flexible, chemically inert connections that protect multi-million dollar membrane arrays.

- High-Pressure Brine Lines: Effortlessly handling the corrosive reject stream from the RO process.

- Chemical Dosing Systems: Reliably transporting chlorine, acids, and anti-scalants without degradation.

- Offshore Platform Hydraulics: Protecting critical hydraulic systems from the constant salt spray and harsh conditions on offshore rigs.

- Ship Ballast Water Systems: Ensuring reliable, biofouling-resistant operation for environmental compliance.

Case in Point: An offshore oil and gas platform in the North Sea was experiencing frequent failures of its stainless steel hydraulic lines due to the corrosive marine atmosphere. They retrofitted the system with SUKO’s ePTFE tubing. The result? A 95% reduction in maintenance calls related to hydraulic line corrosion within the first two years of operation, ensuring the platform’s critical safety and operational systems remained online.

Take Control of Your Operations: Secure Your Plant’s Future

The “unseen enemy” of corrosion doesn’t have to win. By moving beyond traditional materials and embracing the superior performance of ePTFE, you can build a more resilient, efficient, and profitable desalination operation.

Investing in the right materials is not an expense; it’s a strategic decision that pays dividends for years to come through reduced maintenance, extended equipment life, and unparalleled peace of mind.

The evidence is clear. The technology is proven. The solution is here.

Are you ready to eliminate corrosion as a variable in your operations?

Don’t let material failure dictate your maintenance schedule and budget. Partner with an expert who understands your challenges and has the solution to conquer them.

- Explore the Solution: Learn more about our specialized Corrosion-Proof Expanded PTFE Tube for Seawater Desalination Plants.

- Discuss Your Project: Our team of experts is ready to understand your specific application and recommend the perfect solution. Contact us today to start the conversation.

- Request a Quote: Email us directly at info@sukoptfe.com with your requirements for a detailed, no-obligation quotation.

Join the growing number of industry leaders who are choosing SUKO’s advanced ePTFE solutions to build the desalination plants of the future.

Frequently Asked Questions (FAQ)

Q1: How is ePTFE different from standard, non-expanded PTFE tubing?

While both are chemically inert, the “expansion” process gives ePTFE several key advantages. It creates a microporous structure that makes the material significantly stronger and more resistant to permeation under pressure. It also enhances its flexibility and gives it unique sealing properties. For high-pressure applications like reverse osmosis, the structural integrity of ePTFE is far superior to standard PTFE.

Q2: What is the operational pressure and temperature range for SUKO’s ePTFE tubing?

Our marine grade ePTFE tubing is designed for demanding conditions. While specific ratings depend on the diameter and wall thickness, our products typically operate comfortably in temperatures from -200°C to +260°C (-328°F to +500°F). Pressure ratings are engineered to meet or exceed the requirements of high-pressure reverse osmosis systems, often handling pressures well over 80 bar (1200 psi). For specific data on your application, please contact our technical team.

Q3: Can ePTFE tubing be used to retrofit existing systems with metal pipes?

Absolutely. This is one of its most powerful applications. ePTFE tubing is flexible and can be supplied with a variety of industry-standard fittings (such as flare or compression fittings) to serve as a “drop-in” replacement for corroded metal or failing plastic pipes. Its flexibility often simplifies installation in tight spaces where rigid piping would be difficult to maneuver. This makes retrofitting a fast and cost-effective way to upgrade your plant’s reliability.

Post time: Jun-27-2025